Page 3 - Physical Look - Inside

As always, we opened up our FSP AURUM Pro 1000W power supply to take a detailed look at what is going on inside. As mentioned earlier in this review, there is no warranty seal, so we are not voiding our five year warranty by carrying out this procedure. That said, there are no user serviceable parts inside, so we do not recommend you to do the same unless you have at least basic electronics knowledge.

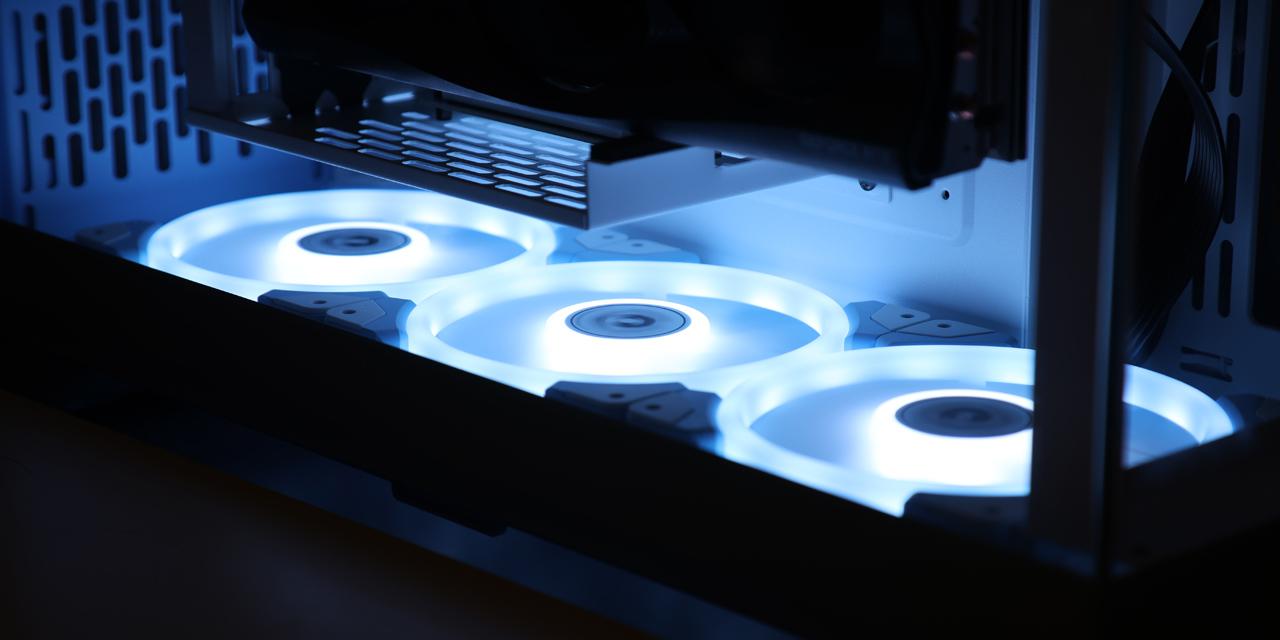

The FSP AURUM Pro 1000W is designed and made by FSP themselves, which is unsurprising, since the company is a large PSU OEM for many other brands. Our photo above shows an overhead view of the FSP AURUM Pro 1000W's internal components. The AURUM Pro is a little more busy than what we have seen in this product line in the past, thanks to a fundamentally different design. The Pro version uses a dual transformer resonant design with a LLC primary and synchronous secondary. Featuring only two small black painted heatsinks inside, with one smaller than the other, is quite an ambitious move. This simple heatsink arrangement along with a loosely packed interior has a lower airflow impedance benefit, so FSP is able to get away with a slow running 135mm fan. We will see how quiet the AURUM Pro is on the next page, but for now, I am not going to waste any of your time -- let's take a closer look.

A quick tug on the shell, and we got straight to the internal inspection. The transient filter stage is the first input stage of a computer power supply, so we will take a look at that first. FSP has done a great job in the past to make sure their power supplies met or exceeded the recommended requirements, and the AURUM Pro series is certainly no exception. The FSP AURUM Pro 1000W has two ferrite coils, one metal oxide varistor, three metalized polyester X-capacitors, and four ceramic Y-capacitors. That is three times the amount of X capacitors and twice the amount of Y capacitors than recommended. Considering how many modern day PSUs have missing MOVs, I am happy to see it here, as this component is used to stabilize spikes from the AC line. We can also spot a unique component, a CAPZero Zero Loss Automatic X Capacitor Discharge IC, to further reduce conversion loss from the AC input.

On the primary side, we can see two Japanese brand Nippon Chemi-Con capacitors connected in parallel. Japanese brand capacitors are usually what we expect from something in this price range, so this is nothing surprising. Our 1000W version of FSP's AURUM Pro incorporates two 390µF x 450V capacitors for a total capacitance equivalence of a single 780µF x 450V capacitor (Remember that values add up when capacitors are hooked up in parallel, unlike resistors). These units are rated at 105c; whereas more value oriented power supplies usually use 85c rated capacitors.

The active PFC circuit featured on the FSP AURUM Pro 1000W uses three Shindengen LL15XB60 bridge diodes, and is controlled by an Infineon ICE2PCS02 standalone PFC controller. At 115V, the maximum rectified forward current capacity with heatsink is 15A for each diode, so you can theoretically pull up to 3450W (15A * 2 diodes * 115V) from the bridge diodes at 100% efficiency -- of course, this is limited by the fact that it is not 100% efficient, and also neglects the fact that not every component in the system are able to keep up. Of course, the goal of having three rectifiers is not necessarily for big power, but for big efficiency. One Cree Inc. C3D06060G silicon carbide Schottky diode and three Infineon IPP60R190E6 power transistors are used on the FSP AURUM Pro 1000W power supply, all of which are attached to a heatsink. Two STMicroelectronics STW26NM60N power MOSFET transistors are attached to the other side. The Cree C3D06060G diode can supply up to 6A continuously at 110c. Each Infineon IPP60R190E6 MOFSET can deliver up to 12.8A at 100 degrees Celsius continuously. These transistors present a maximum resistance of 0.19 ohm when turned on; with a typical resistance of 0.17 ohm according to the manufacturer's data sheet. The STMicroelectronics STW26NM60N MOSFETs can deliver up to 12.6A at 100 degrees Celsius continuously; with a maximum resistance of 0.165 ohm, and a typical resistance of 0.135 ohm. This on characteristic is called Static Drain-Source On-Resistance, or commonly abbreviated as RDS(on). The more efficient the component is, the lower the RDS(on) value, since it wastes less power with lower resistance. Standby power is further reduced by a SENZero SEN012-013 integrated circuit.

On the secondary side, we can see more Nippon Chemi-Con 105c capacitors, but FSP also threw in a mix of Rubycons as well. I am pleasantly surprised by this, as most companies usually resort to cheaper Taiwanese 85c units for secondary capacitors. However, an array of solid state capacitors found in the middle are actually made by Chinese manufacturer CapXon. That said, they do make decent quality products from our experience in the past, so don't be too scared by the name. As with modern high efficiency power supplies, all rectifiers produces the +12V out -- while the +5V and +3.3V outputs are generated from the +12V output using a DC to DC converter within the power supply unit. The +12V rail is generated by a total of eight Infineon IPD036N04LG power transistors (Lower wattage versions of this PSU will have a reduced count of these ICs), located at the back of the main PCB, and uses the PSU housing as the heatsink. Each of them is capable of delivering 87A at 100 degrees Celsius continuously, with a maximum resistance of 0.0036 ohm, and a typical resistance of 0.0030 ohm.

The DC-to-DC converter has one ANPEC APW7159 synchronous buck PWM controller, four APM3116N, and four APM3109N power transistors for its rectification and DC +3.3V/+5V output process, respectively. It was actually really hard to see, haha. I actually had to clean out the transistor's surface, stick a flashlight in there along with a camera in order to identify the markings. Unfortunately, with all this work, I cannot find any information on the APM3116N and APM3109N on the internet, so I have no idea what its specifications are. Meanwhile, a Silicon Touch PS229 IC provides over/under current and over/under voltage protection on a nearby vertical PCB.

At the back, we have a medium sized daughterboard at the rear panel for the modular cable sockets. After the secondary stage, all the wires lead into the secondary board, as shown in our photo above. The output connector configuration can be seen on the previous page. Overall, the internal build quality of FSP AURUM Pro's 1000W power supply is very good -- certainly an overbuilt power supply purely based on parts selection. Components are arranged beautifully for optimal cooling with minimal wires running around inside, and solder points on its black PCB is very clean in general. I would say the FSP branded, FSP built AURUM Pro 1000W is almost spot on with regards to the selection of components used under the hood.

Lastly, we can see a large 135mm fan that provides cooling to the FSP AURUM Pro 1000W's internal components. It is connected to the PSU directly via a soldered 2-pin connector. This is almost the largest fan you can fit in a standard ATX power supply. With an overhead design, it can provide lots of airflow at lower speeds for quiet operation in most cases. Power Logic is the fan OEM, as shown in our photo above. Further research indicates the PLA13525S12M is a hydro dynamic bearing fan specified at 0.4A with a maximum of speed of 2000 rpm. The rated airflow is 111.0 CFM at 41.6 dB of noise with 3.53 mm-H2O of static pressure. There are other versions of this fan available (Namely, available in different bearings), but this one is, in fact, the hydro dynamic version.

Page Index

1. Introduction, Packaging, Specifications

2. Physical Look - Outside

3. Physical Look - Inside

4. Minor Tests and Conclusion