Page 3 - Physical Look - Inside

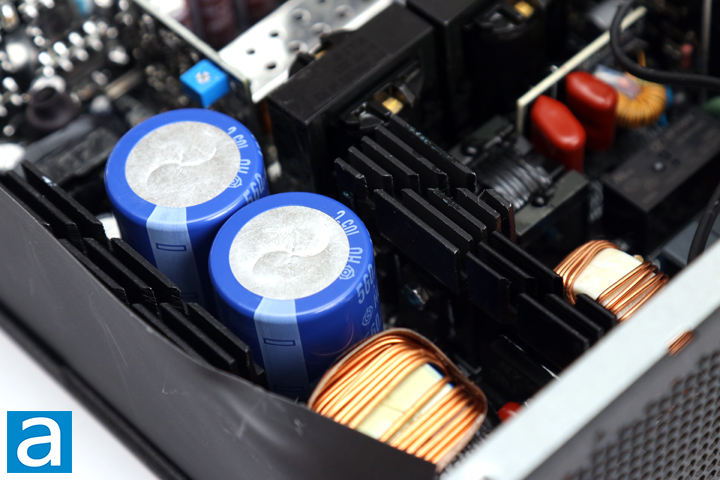

As usual, we opened up our FSP Hydro PTM Pro 1200W so that you do not need to. The four screws to get inside can be found on the fan side of the power supply. One of these screws is covered by a warranty seal, so opening up your unit may void the included ten-year warranty. There are zero user-serviceable parts inside anyway, so I would not recommend opening your own unit up. Once the four screws are removed, you can slide apart the top and bottom shells to get inside. The OEM for the FSP Hydro PTM Pro 1200W is unsurprisingly FSP. The photo above shows an overhead view of the internal components. Build quality from a construction standpoint is good with very few apparent globs of glue. The sides are also shielded with a plastic shield to prevent shorts from the daughterboard or other components here. Otherwise, there are two sets of black heatsinks with a black finish. According to FSP, the whole power supply, including the internals, have been treated with a conformal coating to protect the surface from other conditions such as higher humidity. I doubt you want to be playing with water around an operating power supply regardless of the surface finish, but this is an interesting touch.

Starting at the transient filter stage, there are a total of three X-capacitors and four Y-capacitors near or around the AC receptacle. This is at least twice the number recommended for both of these capacitors, which is great to see. There are also two ferrite coils and a metal-oxide varistor here. The MOV helps with suppressing voltage spikes. Found near here is also an NTC thermistor, which is used to suppress high inrush currents.

Moving further in, we are greeted with two blue capacitors connected in parallel. These are Hitachi HU capacitors made in Japan, each with a rating of 560uF at 450V. They also have temperature ratings of 105c. The Hitachi HU capacitor has been found in many high-end higher-wattage power supplies and is generally a good option, especially with the higher temperature rating. Cheaper power supplies may opt for a capacitor from a Chinese brand or with a lower 85c temperature rating.

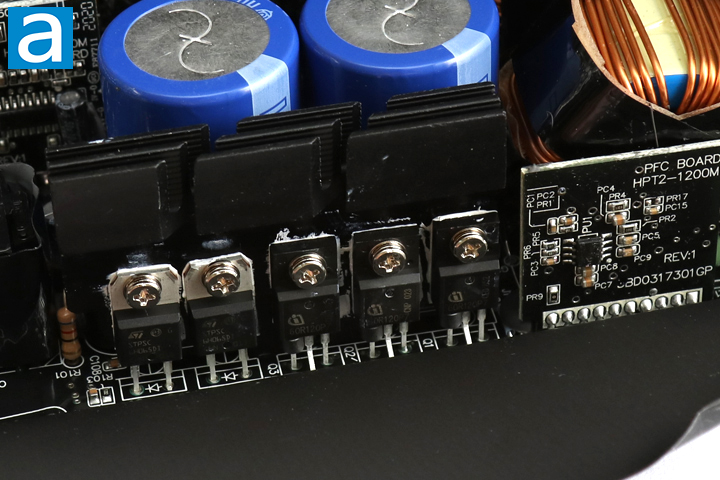

Continuing on, the FSP Hydro PTM Pro 1200W uses two HY GBJ2506P rectifying bridges. This supports up to 25A of current at 100c. At 115V, the theoretical power you can pull from the two bridge rectifiers is 5750W at 100% efficiency. Of course, this is purely from the bridge rectifier, and not all components in the power supply can actually hold this workload. Even so, this is well above the necessary requirements for a 1200W power supply. The active PFC circuit in the FSP Hydro PTM Pro 1200W is located on a black heatsink near the primary capacitor. The active PFC circuitry is handled by three Infineon IPA60R120P7. This transistor is rated to deliver 16A at 100 degrees Celsius continuously with a typical resistance of 0.12 ohm. Two more boost diodes can be found on the same heatsink, and these are two STMicroelectronics STPSC6H065DI. Finally, the main switchers can be found on another heatsink, and these are four STMicroelectronics STF26NM60N. This has a drain-to-source voltage of 600V, continuous drain current of 12.6A at 100 degrees Celsius, and resistance of 0.165 ohm. These on characteristics are called Static Drain-Source On-Resistance or commonly abbreviated as RDS(on). The more efficient the component is, the lower the RDS(on) value, since it wastes less power with lower resistance. Finally, active PFC and switching logic is controlled by a Champion CM6901T2X.

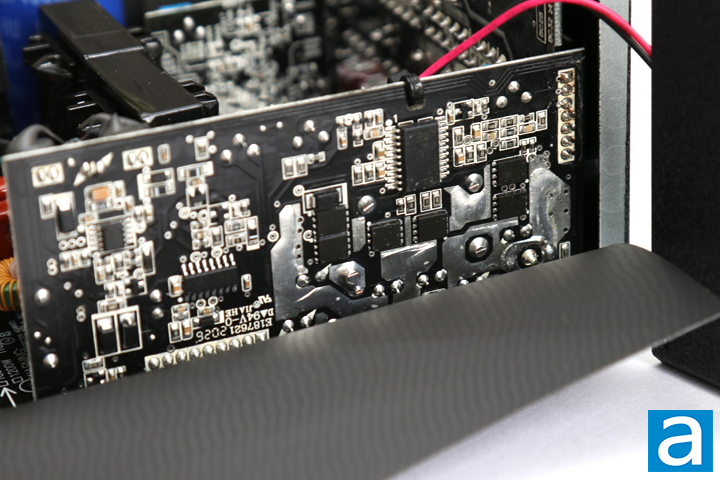

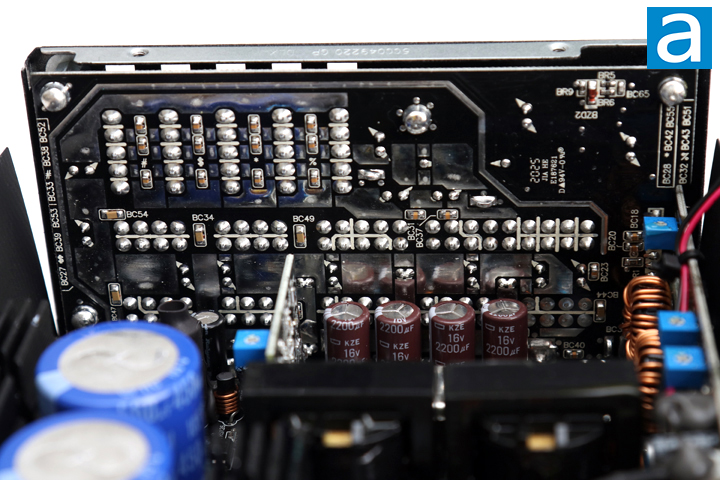

On the secondary side, we can see more capacitors rated at 105c. These are all from reputable brands like Hitachi, Chemi-Con, and Rubycon. All rectifiers produce the +12V out, while the +5V and +3.3V outputs are generated from the +12V output using a DC-to-DC converter within as with modern high efficiency power supplies. Eight Toshiba TPHR8504PL MOSFETs are responsible for generating the +12V output, located at the bottom of the PCB, not shown. I will say it was quite hard to find the model number, especially as most of them had labels that were almost illegible. The rated continuous drain current of the TPHR8504PL is 150A, RDS(on) value of 0.00085 ohm maximum, and 0.0007 ohm typical at 25c. The specifications for 100c were not listed. The +5V and +3.3V output is generated by six Infineon BSC0901NS MOSFETs on the daughterboard pictured above. The BSC0901NS's rated continuous drain current is 94A at 100c. It has an RDS(on) value of 0.0019 ohm maximum and 0.0016 ohm typical. ANPEC's APW7159C is the PWM switching controller. Finally, an SITI PS223H monitoring IC provides over current and over/under voltage protection. The datasheets for all components mentioned in this review can be found on their respective manufacturer's websites.

At the back, we have a large daughterboard covering the entire rear panel for the modular cable sockets. All modular sockets at the bottom are soldered directly to the main PCB after the secondary stage to reduce power transmission loss. The output connector configuration can be seen on the previous page. Overall, the internal build quality of the FSP Hydro PTM Pro 1200W is excellent. Components are arranged well to ensure there is cooling for all the necessary parts, while there are minimal wires running around inside. Solder points on the black PCB is clean with no extra solder here. Component selection is also quite good with reputable brands and components used throughout, although this should be expected for a power supply of this caliber.

As for cooling, a single 135mm Protechnic Electric MGA13512XF-A25 fan is provided, connected to the secondary stage daughterboard of the power supply. This uses fluid dynamic bearings, which should mean it can operate quietly and for longer periods. From the label you can see this fan operates at 12V and 0.38A and is rated to rotate at a maximum 2300RPM.

Page Index

1. Introduction, Packaging, Specifications

2. Physical Look - Outside

3. Physical Look - Inside

4. Minor Tests and Conclusion